The Cameron Automation Rack & Stack

The Rack & Stack is the second generation of Cameron Automation’s Flooring Nesters. Designed to nest flooring strips up to 5″ wide and bundles up to 7.5′ long, the Rack & Stack is 20% more productive, takes up 1/2 the space, and requires less operator intervention than our previous designs.

What Does the Machine Do?

The Cameron Rack & Stack creates accurate nested flooring bundles. Graders feed random lengths of material into one end of the machine, and the Rack & Stack releases a consistent, nested bundle of flooring out the opposite end. Most importantly, it creates bundles the exact square footage you want to sell, increasing your profits by up to 2.5%. A 2.5% yield savings equates to one extra bundle for every 40 you ship!

What does the software do?

Cameron software is written and supported at our factory in Poughkeepsie, NY. This enables us to provide our customers with updates, changes, and upgrades quickly and often at no charge. In house programmers allow us to react to our customer’s needs rapidly. The software is intuitive, easy to understand.

The Cameron Automation Rack & Stack Software:

- Designs bundles that meet the needs of your customers.

- Measures each and every board so you have all incoming and outgoing data.

- Controls shorts in each bundle by changing software parameters.

- Prints bundle labels (optional).

- Generates reports that include:

- Bundles produced

- Square feet

- Boards processed and more

How it Works

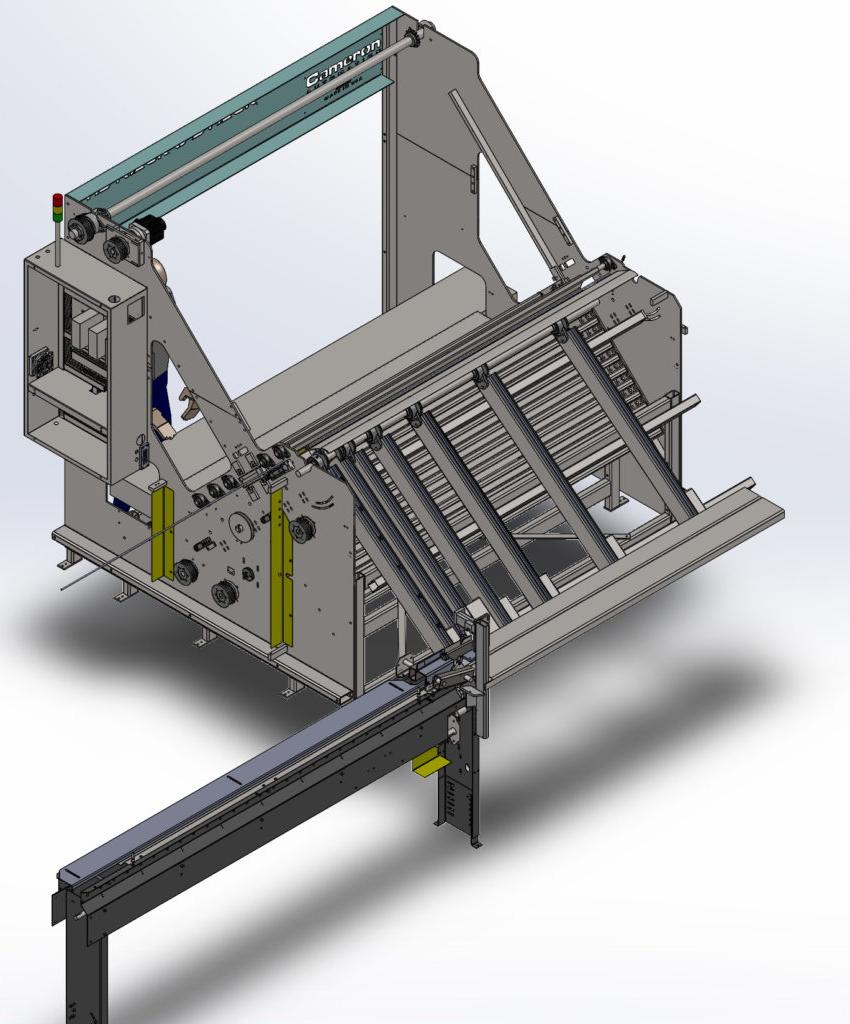

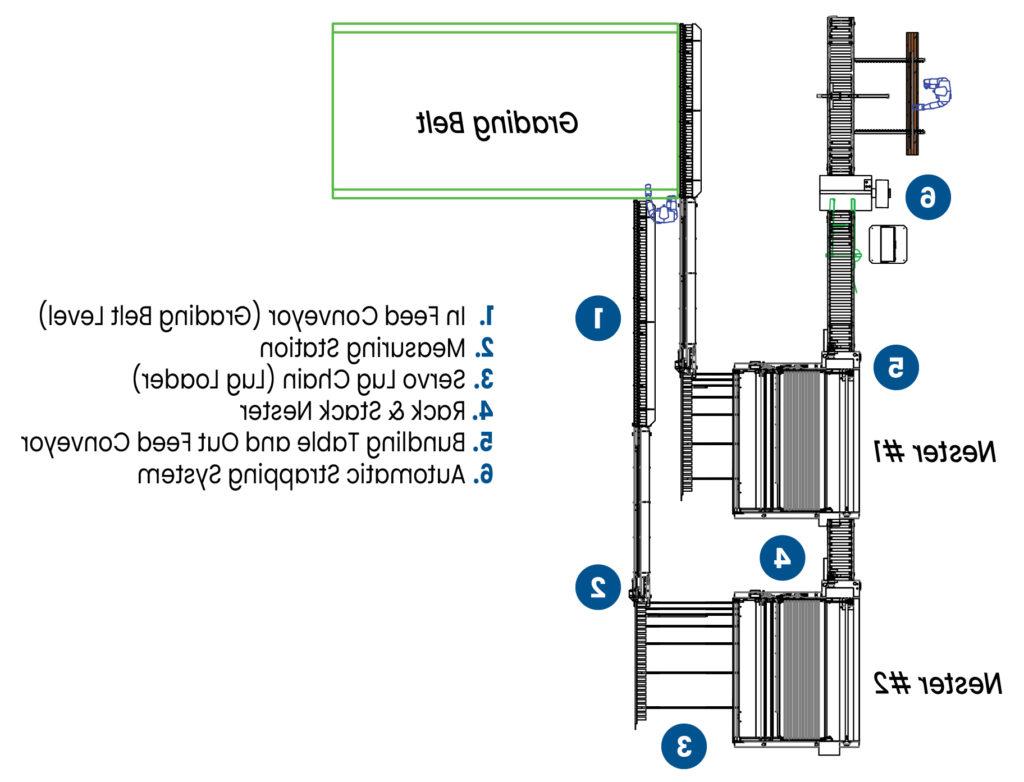

- Infeed Conveyer (Grading Belt Level) Flooring strips of random length are fed from the grading belt onto the in feed conveyor and delivered to the measuring station. The measuring station singulates flooring strips, measures the length and delivers them to the lug chain. The servo lug chain (inclined) lifts flooring strips from the measuring station to the first and second stops at the beginning of the sorting section.

- Rack & Stack Nester (Sorting Station) The rack (with slots) moves up and down continuously delivering the proper strips to build a bundle. When the rack stops, a flooring strip drops out and new flooring strip drops in. With 12 available slots the number of combinations to build accurate lengths and accurate bundles is in the thousands, hence higher yield!

- Bundling Table and Outfeed Conveyer The bundling table is in almost continuous motion gathering and aligning rows and layers of flooring. When a bundle is complete, it is pushed onto the out feed conveyor and delivered to the strapping system.

- Automatic Strapping System The automatic strapping system can be programmed for different strap spacing and different bundle lengths. Strapped bundles are then delivered to the out feed rack for temporary storage.

Information on the Out-feed Systems for the Nester can be found below

Contact us today to learn more about the Rack & Stack and how it can benefit your business!